后期怎么對中空設備進行護

時間:2024-01-24 來源:http://www.aabrs.cn/ 發布人:昌盛機械

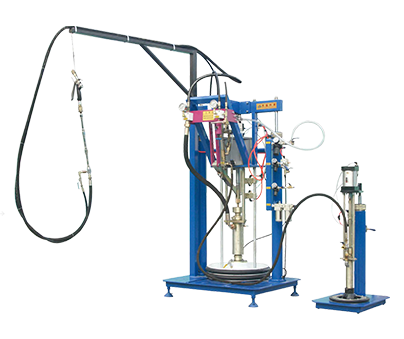

中空玻璃設備就是指用來加工制作中空玻璃的機械設備,主要包括清洗設備、合片設備和涂膠設備。隨著中空玻璃尤其在建筑業中的廣泛應用,中空玻璃設備更受歡迎。下面我們就來了解一下中空玻璃設備的性能要求。

Hollow glass equipment refers to mechanical equipment used to process and produce hollow glass, mainly including cleaning equipment, laminating equipment, and gluing equipment. With the widespread application of insulated glass, especially in the construction industry, insulated glass equipment is becoming more popular. Now let's take a look at the performance requirements of insulated glass equipment.

1、中空玻璃設備密封在試驗壓力低于環境氣壓10±0.5KPa, 厚度增長須≥0.8mm,在該氣壓下保持2.5后,厚度增長偏差<15%為滲漏全部試樣不允許有滲漏現象。

1. When the sealing pressure of the insulated glass equipment is 10 ± 0.5KPa lower than the ambient air pressure, the thickness growth must be ≥ 0.8mm. After maintaining 2.5 at this air pressure, a thickness growth deviation of<15% is considered as leakage. All samples are not allowed to have leakage.

2、露點將露點儀溫度降到≤-40度,使露點儀與試樣表面接觸,全部試樣內表面無結露或結霜。

2. Dew point: Reduce the temperature of the dew point meter to ≤ -40 degrees Celsius, so that the dew point meter comes into contact with the surface of the sample, and there is no condensation or frost on the inner surface of all samples.

3、紫外線照射紫外線照射168h,中空玻璃內表面不得有結霧和污染的痕跡。

3. UV irradiation: After 168 hours of exposure, there should be no signs of fogging or contamination on the inner surface of the hollow glass.

本文由中空玻璃加工設備提供技術支持,更多的詳細精彩內容請點擊我們的網站http://www.aabrs.cn,我們將會全心全意為您提供滿意的服務。

This article provides technical support from insulated glass processing equipment. For more detailed and exciting content, please click on our website http://www.aabrs.cn We will wholeheartedly provide you with satisfactory service.

- 封膠線麻煩?全自動封膠線了解一下 2025/04/01

- 中空玻璃加工設備:建筑節能革命的核心引擎 2025/03/31

- 中空玻璃生產線的概述 2025/03/28

- 全自動鋁條折彎機安全操作流程 2025/03/24

- 全自動封膠線的好處有哪些? 2025/03/24

- 雙組份打膠機的工作原理和優勢是什么? 2025/03/21

- 全自動鋁條折彎機:鋁加工行業的高效利器 2025/03/20

- 全自動封膠線是工業制造的高效粘結助力! 2025/03/18

- 中空玻璃加工設備怎么開啟高效節能玻璃制造新時代? 2025/03/18

- 你知道中空玻璃生產線是建筑玻璃制造的核心力量嗎? 2025/03/17

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us